File Setup

Understanding Options for Saving to PDF

Laying Out Documents for Print

Creating and Exporting Bleeds Using Adobe InDesign

Using Adobe InDesign's Print Booklet Plug-In

Creating a Cutting Path for the Roland

Understanding Paper Options for Digital Printing

This document is intended to provide understanding of the paper options available for toner-based printing. Many of the facts provided are industry-wide, while others may be in regards to printing in the Digital Publishing Center (DPC).

Alternative Resources

For a more in-depth understanding of this topic, we recommend the following School of Print Media class: Digital Asset Management. If you have questions, please consult your instructor or a DPC Customer Service Representative (CSR).

Important Facts

For many designers, paper is the last consideration in the design process. However, with today’s array of paper options and technical considerations in the printing process, designers are becoming more conscious of how their design choices will be influenced by their choice of paper.

Paper Size

One of the most important aspects about paper for digital printing (specifically, toner-based) is the size of paper available. This document will focus on toner-based printing due to its availability in the DPC.

Currently, in the US, the most commonly used digital paper sizes are 8.5" by 11" (US Letter), 11" by 17" (US Tabloid), and 12" by 18". However, many devices are adapting slightly larger sizes, such as 13" by 19" or 14" by 20". In the DPC, most devices will only print up to 12" by 18", with the exception of the Canon C1, which accepts 13" by 19" paper. However, we currently do not stock paper at this size.

Software Options for Imposing Multi-Page Documents

For designers, these sizes will determine the document size limitations of their work. Along with these sizes, device manufacturers have set imageable area limits (e.g. how close the image can be printed to edge of the sheet). Most limit the image area to 0.125" to 0.25" of the edge of the sheet. For example, if the final folded size for a full-bleed document is 11" by 17", the printed image size (with bleeds and crop marks) will be about 11.58" by 17.58" (Figure 1). Therefore, this design requires a 12" by 18" sheet of paper.

Figure 1: Bi-fold letter size brochure with bleeds and crop marks

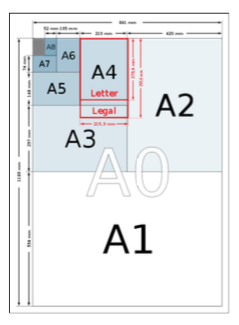

Outside the United States, paper sizes are specified by ISO 216 representing several particular aspect ratios. For example, in the A series, A0 is equal to 1 meter squared, A1 is half of A0, A2 is half of A1, A3 is half of A2, A4 is half of A3, and so on.

Figure 2: ISO 216,A Series

Paper Grade Basis Weight, and Grammage

Another important consideration is the paper grade and weight. For designers and even printers, this concept can be somewhat confusing. In the US, paper manufacturers specify paper by its grade and basis weight. Grade also influences the weight of paper because it determines the paper’s parent size. However, in other countries, it is specified by grams per square meter (gsm).

Paper Grade

The term “paper grade” refers to the classification of paper based on type of pulp, treatments, and the end use of the paper. For printing, common grades include bond, book, coated, cover, index, label, newsprint, offset, tag, and text. For toner-based digital printing, the most common grades are text and cover. Years ago, both grades were named for their role in printing (e.g. text for the inside text of books and cover for the cover of books).

Paper Basis Weight

The classification of weight is derived from 500 sheets of a stock, also known as a ream. For example, 500 sheets of “Text Paper A” may be 80 pounds (written as 80# Text). However, 500 sheets of “Cover Paper B” may also be 80 pounds (written as 80# Cover). The confusing part is that if you had a letter size sheet of each paper (Text Paper A and Cover Paper B), they would not weigh the same amount.

The reason for this is that measurement of the 500 sheets of Text Paper A was taken from standard size sheets (also known as the “basis size” or “parent sheet size”) that were 25" x 38". Cover Paper B was also measured in its standard size, which is 20" x 26".

Paper Grammage

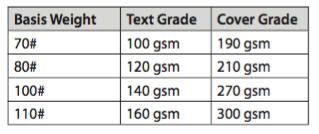

Outside of the US, a standard weight measurement system used in most parts of the world is called grammage. This is expressed in grams per square meter. Unlike the system used in the US, this system does not depend on paper grade (e.g. text, cover). Therefore, if Text Paper A (see previous paragraph) would be approximately 120 gsm and Cover Paper B would be approximately 210 gsm. They would no longer need to be identified by grade because the distinction is made by the difference in grammage. See Table 1 (next page) for common conversions from basis weight to gsm.

Table 1: Typical basis weight to grammage conversions

Paper Caliber

This describes the thickness of the paper. This usually correlates to the basis weight or grammage, however, not always directly. In the US, this is measured in thousands of an inch and called “mils” or “points”. In the rest of the world, this is measured in millimeters.

Design Considerations

As a designer, these characteristics will influence the final design product. For example, for a folded brochure, using a heavier stock (over 80# cover or 210 gsm) may resist folding, which would cause the brochure to flip open rather than stay folded flat. Another example of this would be a saddle-stitch book that uses heavier stock, causing it to open up.

Paper Coating

Another important consideration is the type of coating to seal the stock. There are many options available for paper coating, but the most popular for toner-based printing are gloss, matte, and uncoated. For example, it is typical to see gloss coated paper, commonly used for magazine covers, matte coated paper, commonly used inside of a magazine, and uncoated commonly used inside of a book.

Design Considerations

For designers, paper coating is both an important optical and functional property. As an optical property, it determines how well the reader may be able to read the text. For example, designing a long book to be printed on a glossy paper is not common practice because of the distracting reflections off of the glossy paper surface. Rather, it is more common to used uncoated paper.

As a functional property, paper coating determines how functional the design will be for the document user. For example, it is not common practice to design a form that is to be filled out using a pen on coated (gloss or matte) paper as it is hard for the pen’s ink to be absorbed. For this instance, it would be wiser to use an uncoated paper.

Another factor to remember when choosing a paper coating is the printing process. In the case of toner-based digital printing, the fuser (the mechanism that uses temperature to adhere the toner particles to the paper) will affect the amount of moisture left in the paper. The less moisture, the more the paper will curl. However, coating will help prevent this. For example, if business cards are printed on uncoated, cover weight paper on toner-based device, they are likely to curl. If printed on a coated, cover weight paper, they will be less likely to curl.

Another important consideration for designs being printed on a toner-based device is that the final print could have a shiny, waxy finish due to the toner. Therefore, if there is heavy toner coverage on the sheet, even a matte coated paper will appear glossy. This is also dependent on the toner and device.